Foiling for Print

Have you ever marveled at the metallic, shiny logos and text featured on strut cards, flyers, and product packaging boxes? This effect is achieved through foil stamping, also known as foiling, a subtle yet elegant method of enhancing printed designs. At Strut Cards, you have the option of incorporating foil stamping into your print run through either digital foiling or hot foil stamping. But what distinguishes these two methods? Allow me to provide you with a brief guide, along with information on which option would be best suited for your printing needs

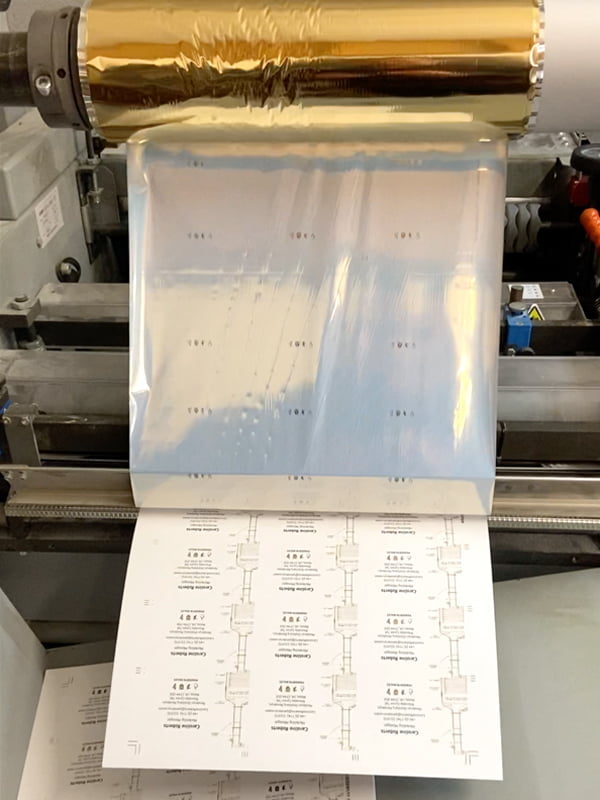

Digital Foiling

If you want a quicker process and a more budget-friendly option, consider digital foiling. This technique only requires a digital graphic file that instructs the digital foil machine to apply the foil onto the paper.

The pros of digital foiling:

Affordable for limited print runs. If you’re only printing a small batch, digital foiling is the cost-efficient choice. It doesn’t make sense to pay extra for a hot foil die if you’re only using it for a few items.

Speedy production. If you’re short on time and need your items printed quickly, digital foiling is the perfect solution. With its quick turnaround, it’s ideal for last-minute print runs!

The cons of digital foiling:

Needs lamination. Digital foiling typically requires a laminated surface to produce a high-quality result. If you were already planning on laminating, this won’t be an issue, but if you prefer a more natural finish, you’re limited to either a matte or soft touch lamination.

Reduced visual appeal. Although digital foiling still looks good, it doesn’t match the presentation quality of hot foil stamping. Instead of being pressed into the paper, the digital foil sits on the surface, which means it doesn’t reflect light as well as hot foil, though the difference is relatively minor.

Digital foiling at Better Printing

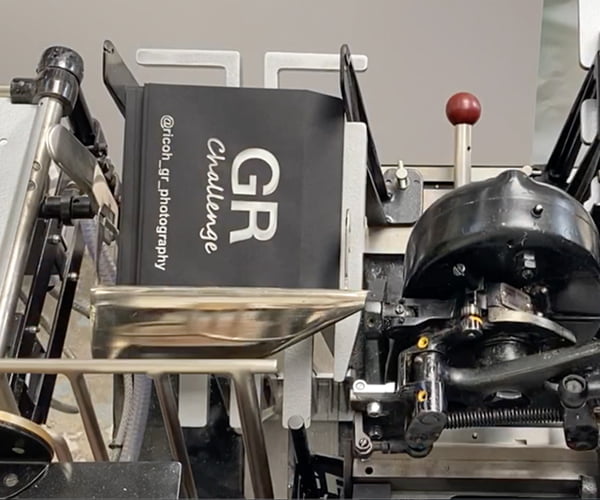

Hot foil stamping

For premium foil quality, hot foil stamping is the way to go. This method involves using a press that has a custom-made die, the paper product to be foil-stamped, and a foil sheet in between.

The die is heated and then pressed onto the foil and printed item, transferring the foil only to the areas in contact with the die.

Additional fees. You’ll need to pay an extra charge for the creation of your foiling die, which will depend on the size of the area you want to foil on your printed items. (However, this extra cost won’t be a big issue if you’re printing a large quantity of foil-stamped items.)

Custom brass die block for foiling

Coloured hot stamping foils

The pros of hot foil stamping:

Improved professional results. Hot foiling provides finer detailing for intricate or thin text, and the stamping process slightly indents the foiled elements to give them a subtle, enhanced shine in light.

More cost-effective for larger print runs. Although hot foil stamping may be pricier for small orders, it becomes a more economical choice when printing a large quantity of items.

The cons of hot foil stamping:

Increased production times. The setup process for hot foil stamping can be prolonged due to the production time necessary for creating a custom die. In the event of a last-minute, urgent order, digital foiling is a more suitable option as it does not require the creation of a die and can be completed quickly. However, it’s important to consider the project’s specific requirements before making a choice between hot foil stamping and digital foiling, as hot foil stamping offers greater design detail and a wider range of foil color options.

Whatever your choice, Strut Card Orinting can provide both digital foiling and hot foil stamping in-house from our Southampton print factory – so there’s no need to worry about extra outsourcing costs.

Hot foil stamping machine

If you have any additional questions about any type of foiling then call us on 023 8087 8037 or email us.