Die Cutting Explained

Have you ever come across products that are die-cut into a custom shape? But what exactly does that mean? And more importantly, how can it enhance your printed product? In this guide, you will learn everything you need to know about die cutting.

What is Die Cutting

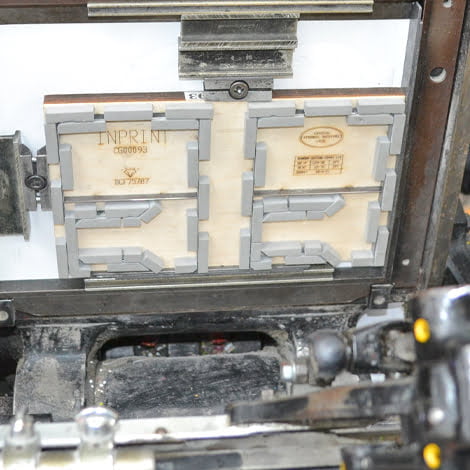

The printing industry makes use of die cutting to efficiently produce identical shapes for a large number of printed items. By printing your design on a square or rectangular sheet of paper or cardstock, it can then be placed into a machine that has been loaded with a custom-made die or punch block, consisting of a metal blade embedded in a wooden block shaped to your specifications.

When the machine applies pressure to the printed sheet and the die, it instantly cuts out the shape of the blade from the material. This process can be used to produce a wide range of items, including strut cards, invitations, packaging, and promotional products, on materials like paper, cardstock, vinyl, foam board, and more.

Die cutting provides a cost-effective solution for large print runs, as it can be done quickly and accurately in high volume. Additionally, it allows for the creation of unique, intricate shapes and can be used to add finishing touches, such as rounded corners or a special edge, to your printed products.

Die cutting is for more than just eye catching custom shaped flyers however, it also helps create the more functional aspects of printed products such as pockets and flaps on folders and boxes plus the curves, circles and intricate interlocking elements on our speciality print.

Die cut block

Block mounted on platten

Custom cut boxes

Why is die-cutting beneficial?

Die-cutting streamlines the process of creating custom shapes, eliminating the need for a digital cutter to meticulously maneuver through each curve and corner. With a custom-made die, you can produce hundreds of identical, custom-shaped products in one swift motion. Moreover, the die can be reused repeatedly, providing an efficient and cost-effective solution for high-volume production.

Which materials can be die-cut?

It’s important to note that die-cutting is best suited for low strength materials, such as paper and card, due to the punch-out style of cutting. The minimum recommended paper weight for die-cutting is 170gsm, equivalent to 140microns in thickness, and the maximum recommended weight is 500gsm, or 600microns. When selecting the right material for die-cutting, it’s important to consider the thickness, as it is measured in thousandths of a millimeter (microns).

What about foamboard, correx and dibond?

When it comes to heavier weight materials, such as large format materials, a different approach is necessary. Digital die cutting is the solution in these cases, as it uses a computer-programmed blade rather than physical dies to create the shape.

A digital cutting machine comprises of a flat table surface and a cutting, milling, and scoring attachment mounted on a flexible arm. This arm allows the cutter to move in multiple directions, such as left, right, forwards, and backwards.

To use digital die cutting, the printed sheet is placed on the table, and the cutter follows the programmed path to cut out the desired shape. This process is highly precise and accurate, making it suitable for materials with a heavier weight that cannot be effectively cut using traditional die cutting methods.

Digital die cut paper and card

With the advancements in technology, it is now possible to achieve high-quality “die-free” cutting on a wide range of paper and card weights, including strut card. This innovative solution offers the benefits of reduced cost and production time, as it eliminates the need for a costly die block.

Although digital die cutting may not match the volume output of traditional die cutting, it offers a practical option for low-volume print runs or prototypes for larger die cutting forms. Its precision and accuracy make it the perfect choice for projects that do not require a large volume of identical cuts.

Digitally cut cake box

If you have any more questions about die cutting, traditional or digital call us on 023 8087 8037 or email us.